Cool Down is a Critical Requirement in Food Safety

A widely misunderstood requirement in food safety is the cooling down of foods that have been brought to cooking temperature and then cooled for storage or further processing.

A widely misunderstood requirement in food safety is the cooling down of foods that have been brought to cooking temperature and then cooled for storage or further processing.

Why is the time to reach the proper temperature so important? The answer is the food safety “red zone”. If food in the process of being chilled stays warm too long, there is a very real possibility that harmful microbes can multiply in the food product when it is passing through the temperature range that accelerates the growth of pathogens in the food.

The answer is to monitor the rate of cooling, and to apply chilling methods that make the time at the critical temperatures minimal. Most regulations require documentation of this process and some type of instrumentation to monitor the temperature during critical cool down.

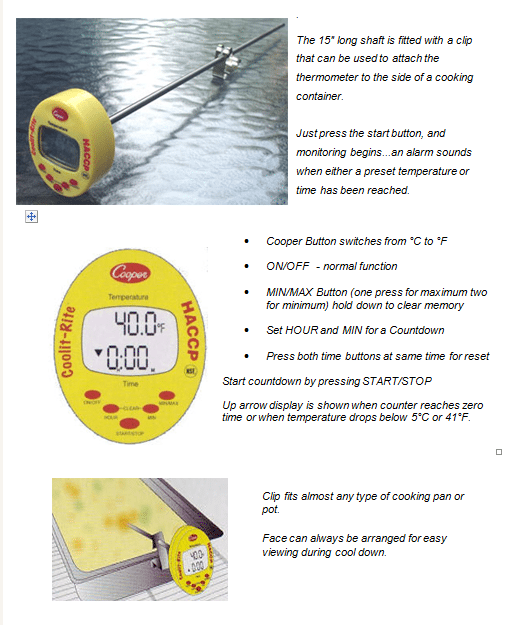

Our AQA4100 is ideal for this process.

Product Specifications

| Temperature Range | – 4°F to 302°F (-20°C to +150°C) (user switchable °F or C) |

| Temperature Accuracy | ± 2°F from -4°F to +212°F ( ±1°C from -20°C to +150°C) |

| Timer | Timer Range up to 7 hours – timer accurate to 3 seconds/day |

| Convenience Features | Extended handle with clip |

| Probe | Stainless Steel 1/8″ diameter 15″ long |

| Battery | LR44 Coin Cell User Replaceable |